SOLIDS RECOVERY

LARGE SCALE SOLIDS RECOVERY OPERATIONS

ROTARY VACUUM FILTER

Almost a century ago the ROTARY VACUUM FILTER improved significantly the performance of the above depicted GRAVITY & VACUUM NUTSCHE.

Much higher throughputs with far less labour were achieved. The open design, cake instability, poor cake washing and lack of control are major drawbacks.

VACUUM BELT FILTER

The horizontal VACUUM BELT FILTER, solved many of these problems. However the exposed design and lack of CONTROL have prevented the general acceptance of these types of filters in many industries.

PRESSURE NUTSCHE

This disadvantage of exposed design was overcome by the development of the PRESSURE NUTSCHE which provided completely sealed operation. This advantage was however offset by safety problems, lack of accessibility as well as CONTROL and difficult mechanical solids removal from the sealed container.

BELT PRESS

The BELT MEMBRANE PRESS after a period of popularity, e.g. in the chemical and sugar industry, has lost ground due to the lack of the means of CONTROL, mechanical complexity, chamber sealing problems and the exposed design.

CENTRIFUGAL FILTER

The CENTRIFUGE FILTER fitted with mechanized retractable media for ease of cake removal has found a niche application in the multi-product pharmaceutical and fine chemical industries Drawbacks involve safety considerations inherent mechanical and CONTROL problems.

The MILLER FILTER has proven itself as an ideal apparatus for recovering solids from suspensions in many industries.

PRESSURE BELT FILTER

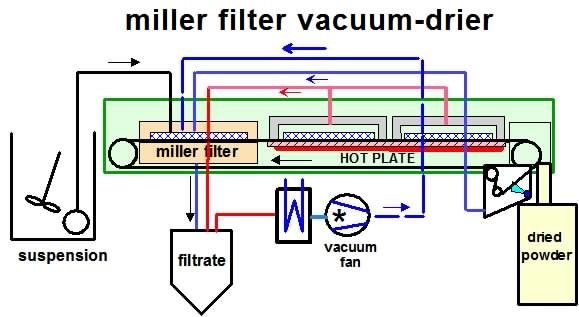

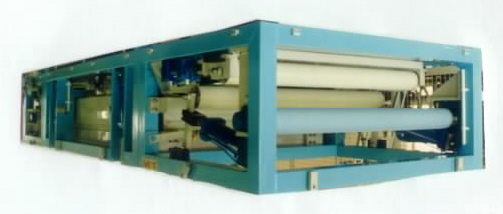

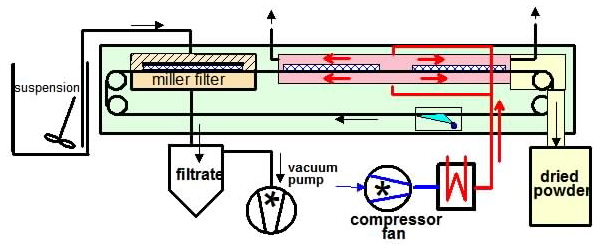

MILLER FILTER

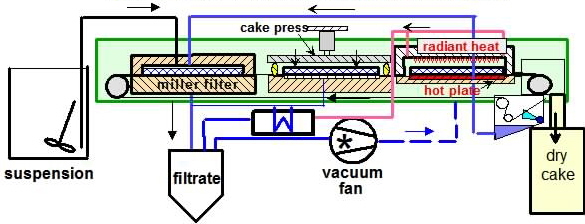

- The suspension is pumped through a standard Miller Filter forming a filter cake that is finally partially de-watered under vacuum.

- The cake is transported on a section of filter belt into the TUNNEL DRIER while the final section of cake already in the drier is discharged as a dried powder to a storage container. The heated gas input is shut down during the transportation.

- The tunnel is resealed and the next drying cycle proceeds.

- During the belt transport a section of belt is washed whereby solids residues on the band are recycled to the suspension tank.

- Contained sealed plants with up to 10m2 of filter area and 20m2 of drying area are available for fully automatic round-the-clock operation.

Especially suited for recovery of heat sensitive solids from suspension in volatile solvents common in pharmaceutical, chemical and food production processes.

OPERATION

OPERATION

- discharging the solvent free end cake to the dried powder container,

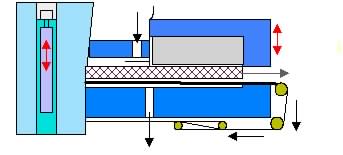

- transporting the filter cake in the MILLER FILTER to the first drying chamber

and - transporting the partially solvent free cake in the first drying chamber to the second drying chamber.

- The filter cake is transported on the filter belt from the Miller Filter to the VACUUM CHAMBERS.

These chambers have a similar design to the Miller Filter.

The cakes and belt sections are supported on a HOT PLATE held at temperatures below the melting point of the solids.

The filter chambers are sealed and made vacuum tight thus forming two independent vacuum cake drying containers.

-the cycle is then repeated-

Many aqueous suspensions requiring dewatering in industrial and municipal processes produce compressible residues prone to crack-building with conventional dewatering methods. Such residues are often the cause of insuperable transporting, further processing and handling difficulties.

The MILLER SOLUTION to these problems is a TANDEM MULTI-MODE DEWATERING MACHINE.

OPERATION

- FILTRATION

Suspension is filtered under positive pressure in the MILLER FILTER forming a partially de-watered filter cake.

- the cycle is repeated -

MILLER FILTER TUNNEL DRIER

Many solids recovery operations involve the formation of thin adhesive cakes which prior art apparatus can handle only with the expenditure of excessive manual labour.

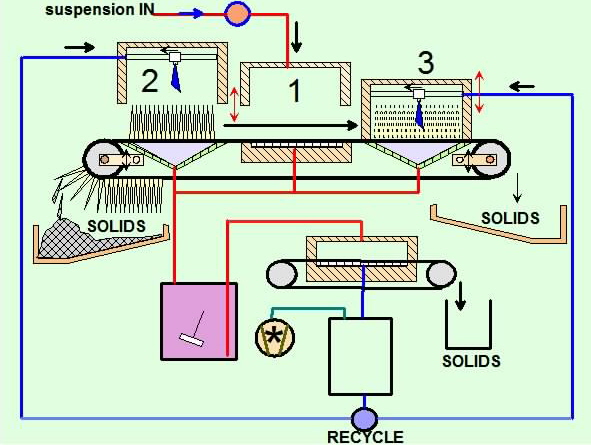

The MILLER UNIVERSAL SYSTEM utilizing SHUTTLE expanded surface elements provides fully automatic solutions to these and a host of other challenging solids recovery operations.

UNIVERSAL SOLIDS RECOVERY SYSTEM

OPERATION

- After primary filtration in the CENTRE SECTION (1) the residues within the elements are de-watered.

- With the chambers opened the belt transports the element (1) through CHAMBER 2 . On passing around the deflection roller the fin-shaped elements flare (open up) and with a simultaneous jolting action of the swing-jointed rollers the solids are dislodged into the skip below.

- Inevitably traces of solids remain in the elements. It is essential to remove and recover these (regeneration) after each cycle. The direction of travel of the belt is now reversed. The previously regenerated element now in (2) is transported into (1) while the soiled element now above the solids container is transported into (2).

All chambers are now sealed.

- Primary filtration in the CENTRE SECTION (1) is resumed.

- The soiled element (2) is subjected to mobile high-pressure jets of cleaning fluid. The extra provision of ULTRA-SONIC cleaning is an added option.

- The suspensions generated are collected and filtered in a standard MILLER solids recovery filter whereby the filtered liquid is recycled to the SHUTTLE for further element regeneration.

- On the following cycle the used element in (1) is transported to the right hand side of the SHUTTLE for solids removal and regeneration in (3) while the previously regenerated element in (2) is transported to (1) for the next filtration operation.

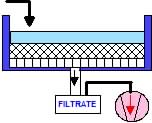

ORIGINATING PROGENITOR: THE NUTSCHE

Despite lacking means of control, open design and mainly manual operation the FILTER PRESS is still seen to be indispensable for many difficult solids separation operation in a wide variety of industries and especially in effluent treatment.

PROGENITOR: FILTER PRESS

GRAVITY & VACUUM

NUTSCHE

The NUTSCHE days are now numbered.

The environmental problems associated with its operation have sealed its demise.

FILTER PRESS

The following chart exemplifies a variety of filter apparatus used for SOLIDS RECOVERY OPERATIONS. Many are derived for the originating NUTSCHE but a sizeable proportion is based on the FILTER PRESS and the BASKET TYPE CENTRIFUGE.

The following examples provide an overview of the wider range of possibilities accruing from this unique mono-planar design principle showing that a universal application accompanied by full automation and an environmentally friendly operation is in the offing.

CAPACITY

Individual SHUTTLE ELEMENTS are fitted with up to 200m2 filter area which operating on cycle times of 20-40 minutes can achieve through-puts far in excess of prior art apparatus.

2. MILLER FILTER TUNNEL DRIER

The MILLER TUNNEL DRIER is ideal for higher melting point solids that can be directly contacted with hot gases.

- Vacuum is applied to both drying chambers and on reaching a set value the drying chamber nearest the MILLER FILTER is isolated from the source of vacuum.

- On attaining a maximum under-pressure in the end drying chamber the source of vacuum is isolated from all chambers, after which they are all vented to the surrounding sealed housing and opened.

- The belt simultaneously transports all three cakes forward thus

- CAKE PRESSING

The partially de-watered cake is transported into the second compartment where it is subjected to mechanical compression by means of a top horizontally mounted hydraulically actuated thick metal plate the surface of which is treated with PTFE and fitted with a special peripheral sealing device. The plate is lowered slowly and incrementally on to the surface of the cake allowing sufficient time to counter the increasing resistance with time to the seepage of liquid through the cake. - CAKE DRYING

In the third compartment a combination of lower hot plate and upper radiant heat supported by vacuum ensures a rapid cake-drying process.

If necessary the solidified cake can be broken into pieces on discharge.

In practice all three operations described above take place simultaneously and fully automatically

MILLER CAKE PRESS VACUUM FILTER-DRIER

Contents of this chapter: