LIQUID PURIFICATION

To-days industrialised nations are plagued by problems related to serious pollution of the fresh water resources. It is nothing less than tragic when one reflects that serious plans are currently being made for future human settlements on other planets where water may exist while at the same time water on our own planet is threatened with ever diminishing reserves of pure fresh water.

The consumption of water on our planet per se means concomitant contamination of the world's fresh water resources.

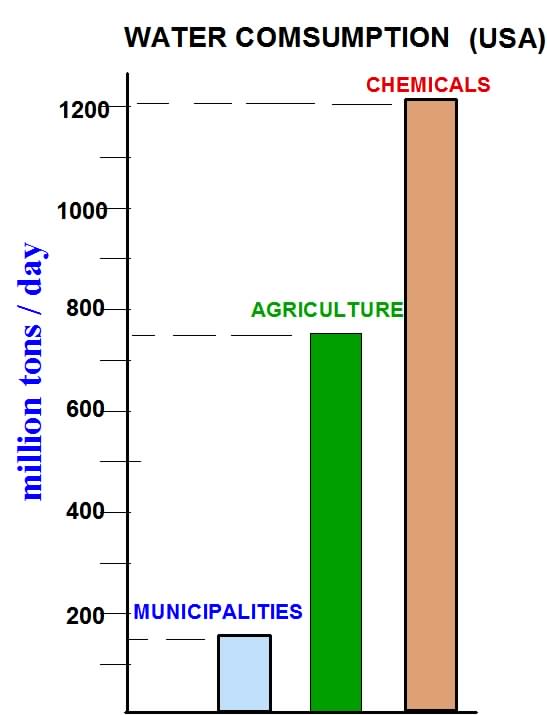

The water consumption value alone in the USA chemical industry depicted on the chart on the right clearly indicates the dominance of industry in the consumption alone and contamination of water in industrialised countries. A large reduction or elimination of this consumption and contamination would leave the agricultural sector as the main contaminating factor of fresh water resources needing urgent legislative counter action.

The following contribution analyses the background that has led to this condition including the legislative paralysis regarding the lack of enforcement of effective measures to solve the present pressing problems regarding industrial effluent.

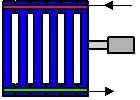

The PROGENITOR of almost all todays liquid purification apparatus, the FILTER PRESS, still finds wide application in a large variety of industries. The major drawback is the inherent exposed design required for access for manual opening, solids removal, medium cleaning or replacement and resealing of the apparatus. Meaningful control of its operation is non-existent.

FILTER PRESS

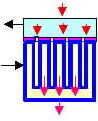

Over past decades the progenitor FILTER PRESS has been largely replaced by a diversity of filter designs with multiple filter elements enclosed within pressure vessels. This solved the exposed design of the FILTER PRESS but at the price of a large number of disadvantages that are becoming increasingly unacceptable:

- The reliance on PRE-COATING with filter aid powders results in acute environmental problems due to the dumping of the inevitable waste-mud often containing toxic substances.

- The inherent long cycle times from 8-24 hours required for the laborious, time consuming procedures for cleaning out the contents of the filters and putting them into operation again.

- The lack of flexibility and control of the operations when the filtrate fails to meet a set quality standard. This frequently leads to the shut down of production until the problem has been manually solved and is often accompanied by serious environmental and maintenance problems.

- Even partially blocked or damaged filter elements often require a major dismantling operation requiring their replacement with a spare set of elements.

- All these filters are major contributors to the pollution of the environment. None are capable of “cleaning up their own mess” and no generally applicable method exists for the REGENERATION and REUSE of the large quantities of used filter aid now dumped into the environment as waste. The environmental damage caused will perhaps be the main cause of their demise.

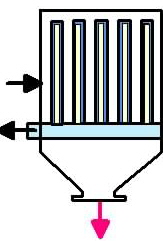

These above listed inherent production and environmental problems associated with pressure pre-coating filters force many manufactures to turn to what are known as CARTRIDGE filters. These are pressure filters with “one-way” replaceable compact elements (often pleated membranous media) with a high ratio of filter area to filter volume. The long cycle time and reliable filtrate quality associated with these filters outweigh the high cost of element replacement.

The standards set for maximum allowable contamination of discharged effluent is generally based on what is considered to be the best quality attainable by the prevailing state-of-the-art fluid purification technology.

The cost aspects of course predominate here. Prior art technology could achieve complete removal of contaminants but the required outlay for capital expenditure and operating costs would in many cases cause the industries concerned to become globally uncompetitive.

On scrutinising this prior art it becomes apparent that in continuing to treat this technology as the most effective available there is no possibility of ever achieving the elimination of contaminants while at the same time preserving the present cost-structure of the production processes.

This dilemma has existed for well over a century and if no

- innovative, cost effective technology to achieve this

or - global enforcement of more costly purification methodologies is forthcoming the liquid environment is heading for an inevitable disaster.

The pressures brought to bear on industries when confronted with fluid purification problems have in the past been mainly driven by the perceived pressures to minimize capital and operating costs. The damage caused by prior art processing plant to the environment has always been a secondary factor when planning or operating plants involved in fluid processing.

MULTIPLE FILTER ELEMENTS

Why two modes of purification?

This is to facilitate media regeneration for large-scale fluid purification.

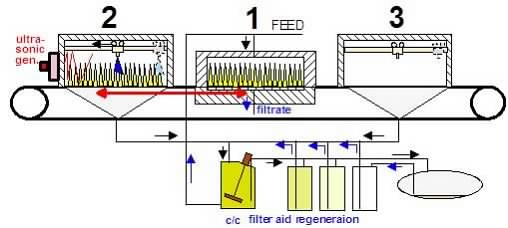

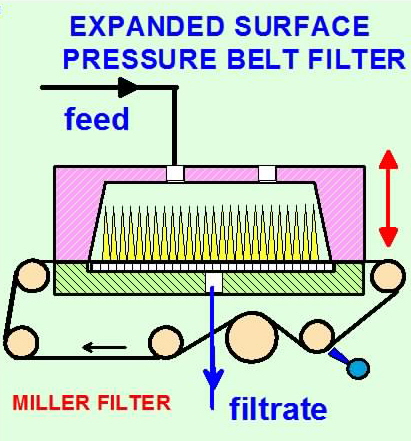

A key goal in the final development stage of the Miller Filter was to design, fabricate and test PLEATED or FOLDED filter elements as an integral part of the transportable filter band. The goal was to exploit the advantages of state of the art compact bundles enclosed in pressure vessels while at the same time eliminating the many disadvantages experienced with these prior art filter designs.

Total Recycling of Industrial Effluent

Innovative designs using this Miller Filter concept have been developed that promise to revolutionise the art of liquid purification across the whole spectrum of industrial liquid purification activities.

For the first time a generally applicable system has been devised for the liquid purifying industries enabling fully automatic liquid purification in the nano-micro particulate size range combined with the economical total recycling and reuse of any resulting waste effluent.

For the first time systems for effluent purification and recycling are available that promise a rapid amortisation of the investment involved.

The operating costs/cubic meter of purified effluent are far below the cost of purchased fresh water.

It can pay off to go GREEN !

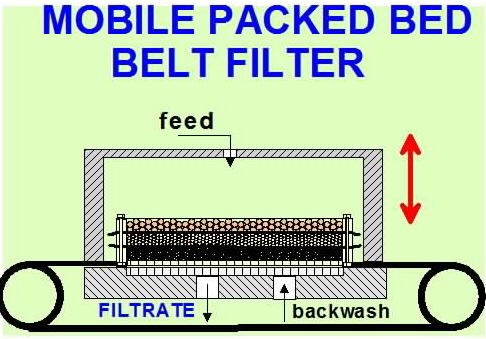

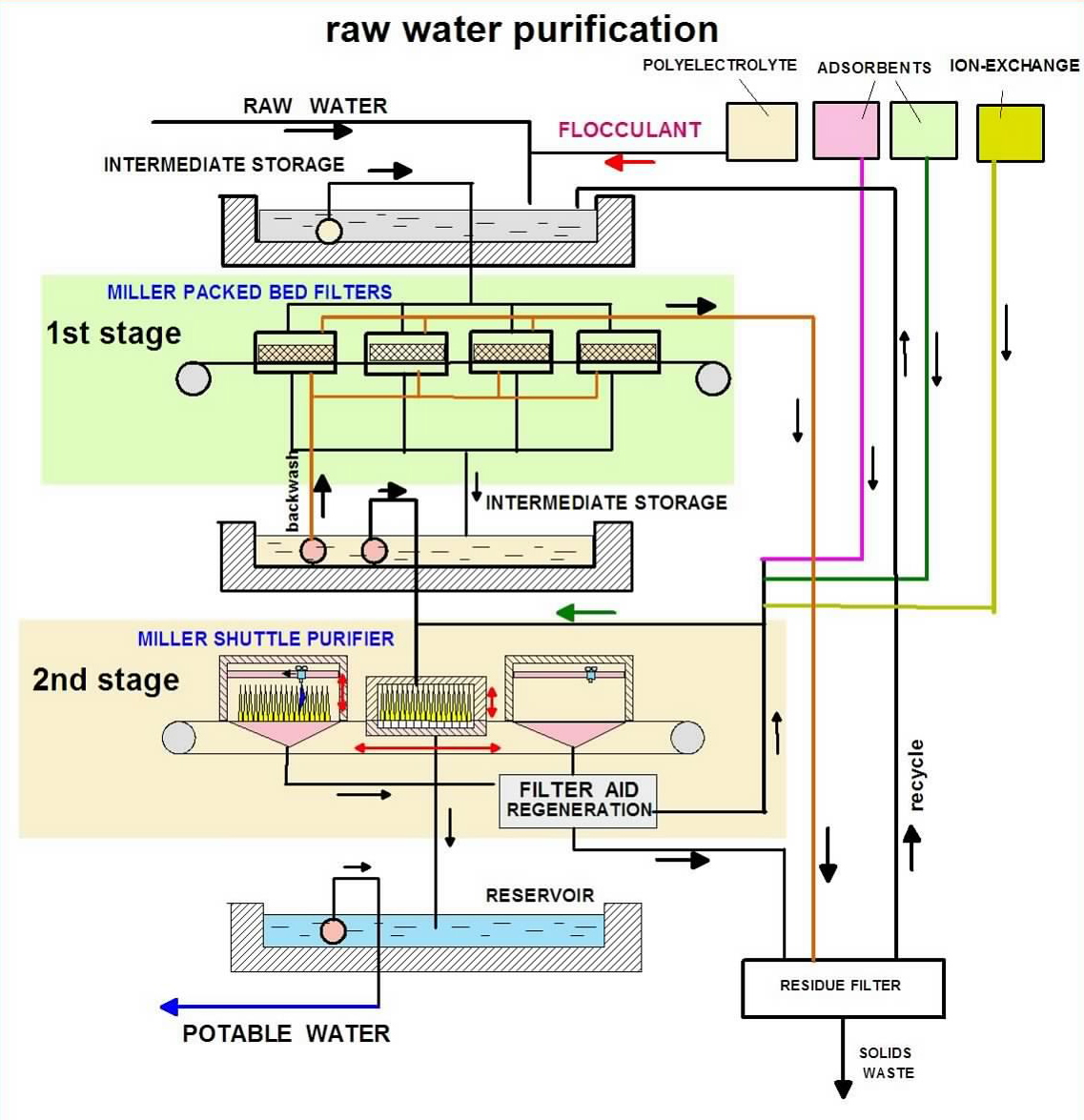

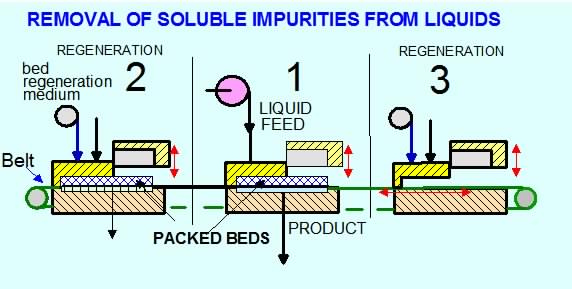

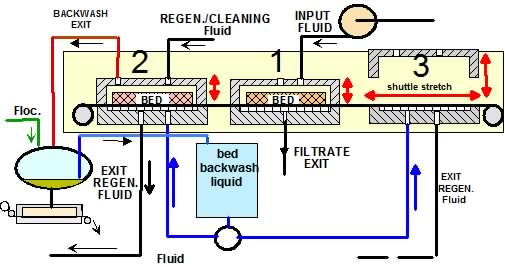

The key to the successful general application of the EXPANDED SURFACE ELEMENTS in large scale liquid purification is the provision of a primary filtration stage with MOBILE PACKED BED FILTERS.

Successful fluid purification in the NAN0-MICRO particulate size-range mostly depends on the application of particulate filter aids and/or membranous media and to render the operations cost-effective they must be regenerated fully automatically and reused on a long-term basis.

Naturally occurring fluids (water and air) especially in or near industrialised areas often contain complex mixtures of suspended matter such as colloids and aerosols that make regeneration of available powdered filter aids and membranous media difficult if not impossible.

The purpose of MOBILE PACKED BEDS as a primary purification stage is to remove most of this material before the second and final purification stage with EXPANDED SURFACE ELEMENTS.

Suitable for primary clarification and filtration of a wide variety of raw liquids.

With judicious use of flocculants and coagulants this mode of purification is characterised by high throughputs and high filtrate quality.

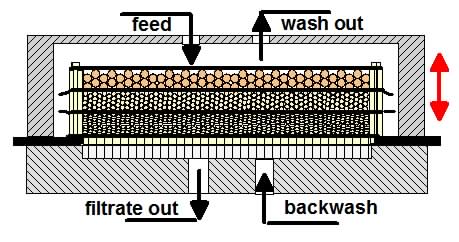

SIZE GRADED LAYERED PACKED BEDS

The centre chamber is used exclusively for the filtration operation where high throughputs accompanied by short cycle times are achieved.

OPERATION

On a set pressure differential the chamber is emptied and the bed is transported to one of the chambers reserved for bed regeneration.

The backwashing operation is initiated with PULSED BACK-WASHING accompanied by sudden successive bed expansions that are extremely effective in removing what are considered to be intractably trapped residues.

APPLICATIONS

- City water primary clarification

- Industrial effluent clarification with recycling

- Primary filtration of raw juice in sugar refining

- Primary filtration of juice from pressed grapes in wine making

- Wort filtration in beer brewing

- Primary filtration of large rnage of raw, liquid products

This MILLER SHUTTLE PRINCIPLE solves the problem of state-of-the-art concerning REGENERATION of the filter elements and media.

In-situ regeneration is plagued with problems such as contamination of the product because of inaccessible residual quantities of the cleaning material remaining on or in the elements. The answer is to move the element bundle to a specially designed regenerator whereby a freshly regenerated pack replaces the previous one to continue the operation with a minimum of delay.

PLANT SIZE:

Single SHUTTLE PLANT with up to 200 m2 filter area out of 20micron polyester monofilament to 0.01micron bonded PTFE membranous material.

200m2 Unit: L = 10m B = 2.50m H = 2m (approx.)

MATERIALS OF CONSTRUCTION:

Wetted surfaces out of any of all the available stainless steel, nickel, etc. alloys and most commercially available thermoplastics.

DESIGN:

Turn-key plants are all fully computer-automated and suitable for round -the-clock operation without manual supervision.

Possible CONTROL programmes include:

- Product quality electronic supervision

- Electronic trouble shooting

- Automatic electronic fault rectification

Performance GUARANTEE:

Where appropriate for WATER RECYCLING applications the customer receives a pay-back guarantee based on savings accruing from the avoidance of water supply costs.

APPLICATIONS:

These extend from STERILE FILTRATION of liquids to SOLIDS REMOVAL AND RECOVERY.

- Pharmaceutical products

- Chemicals

- Food

- Beverages:

- Beer brewing

- Wine making

- Fruit juices - Water:

- Municipal drinking water

- All types of industrial wastewater to meet any global purity standard with pay-back guarantees.

STERILE FILTRATION:

GREEN SOLUTIONS CAN BE LUCRATIVE !

SOLIDS RECOVERY:

A wide range of solids recovery operations can be carried out with EXPANDED SURFACE ELEMENTS.

The advantages are short cycle times and high solids volume recovery rate.

The results of recent trials indicate that a purification system comprising two 20m2 Miller Filter Systems provided with the means for filter bed regeneration and reuse can purify and recycle final effluent from a typical communal sewage system.

Example: Potable water from raw water

The ultimate challenge for any liquid purification system would be the ability to economically produce potable water from what is known as “grey water”.

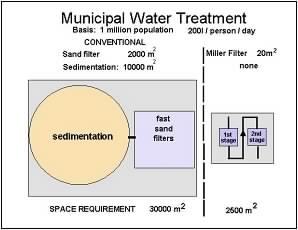

The MILLER System on the right shows a 90% installation space saving compared with state-of-the-art plants that require massive expensive civil engineering construction.

State-of-the-art technology cannot economically produce potable water from “grey water”.

|

COST EXAMPLE (assuming an existing distribution network) |

|

|

Population: |

200.000 |

|

Water consumption/day: |

200 litre/person |

|

Raw water source: |

typical running river water |

|

CAPITAL |

|

|

Stage 1: |

4m2 Miller packed bed sand filter |

|

Stage 2: |

2m2 Miller pleated shuttle band> 200m2 |

|

BUDGET / COST |

|

|

All ancillary equipment, building, reservoirs etc: |

£ 10 M |

|

Amort. 15yr ~ £ 0.7 M/yr: |

£2000/day |

|

RUNNING COST |

|

|

Chemicals: |

~ 100 ppm ~ 4 t/day |

|

+ Power, maintenance, etc |

|

|

+ Labour: 1 man / 3 shift + overhead: |

~ £1500/day |

|

TOTAL: |

~ £3500/day |

|

Cost of water: |

~ 9 p / m3 |

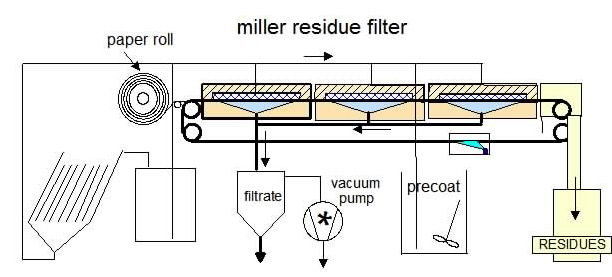

Central to systems for the purification of large throughputs of liquids whether of municipal or industrial origins is a means for clarifying and recycling all miscellaneous fluids from plant cleaning and regeneration residues of the entire process.

The solid residues are isolated and collected for incineration.

The clarified liquids are purified according to the requirements of the particular process for recycling and reuse at the point of original delivery.

- Disposable paper in roll-form is often used for intractable types of solids that often occur in liquid processing plants.

- For high quality liquid filtrate recycling pre-coat filtration is often preferred whereby thin layers of such material as wood meal in a variety of qualities are formed as pre-coat on the sections of band in use.

- Direct filtration on sections of the filter belt is normally employed when the solid residues separate as cakes easily removed from the belt.

OPERATION

COMPLETE TURN-KEY PLANTS ARE AVAILABLE:

- Plate Clarifiers

- Liquid ring vacuum pumps

- Vacuum filtrate tanks

- Precoating facilities

- Microprocessor control equipment

- Pneumatically actuated valves

FILTER SIZES:

- 3 – 10 m2

MATERIALS OF CONSTRUCTION:

- Generally polypropylene for internal wetted as well as external surfaces is preferred.

SS316 is the normal choice for wetted parts of filters and ancillary equipment for handling solvents.

ANCILLARY EQUIPMENT:

- liquid purification,

- extraction,

- catalysis,

- ion-exchange

- liquid/gas reactions.

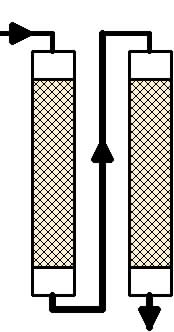

MOBILE PACKED BEDS for rationalizing the state-of-the-art apparatus and methods for contacting FLUIDS with beds for the purpose of

State-of-the-art apparatus for large scale operations using packed beds consist of large columns occupying large spaces.

The material of the beds are invariably of a sizeable granular nature. This is obligatory as the transfer of fluids through finely divided particles packed into columns is impracticable.

This explains the inevitably large size and inflexible nature of conventional plants. The time-cycles are necessarily long as media regeneration operations are often time-consuming and problematic.

EXAMPLES

|

BED MATERIALS |

||||

|

PURIFICATION |

EXTRACTION |

CATALYSIS |

ION-EXCHANGE |

LIQ / GAS REACTION |

|

Activated carbon |

Seeds (veg.) |

Metals (Ni, Pt, Ag) |

Cationic |

Hollow spheres |

|

Silica gel |

Malt |

Metal oxides, Vd, Cr, Mo |

Anionic |

|

|

Kieselguhr |

Plant matter |

Al-silicate, Al-oxide, |

Mixed |

|

|

Fibre-glass |

|

|

|

|

|

Silica (sand) |

|

|

|

|

The MILLER MONO-PLANAR PACKED BED CONCEPT with sections of mobile packed beds provides a compact, high performance solution for such applications.

SHUTTLE-TYPE MOBILITY of the beds enables separate facilities for purification and bed regeneration operations. Dedicated apparatus for both PRODUCTION and BED REGENERATION ensures the availability of a non-contaminated production unit at all times and promotes flexibility of operation.

Compact high-performance systems are achieved with bed materials of the order of 200-500μ particle size and bed thickness of 50-100 mm.

High throughputs combined with much shorter cycle times are achieved.

ADVANTAGES

EXAMPLE A

- Activated carbon

- Silica gel

- Bentonite

- Solvents

- Heated gas

BED MATERIAL

BED REGENERATION

- SILICA GEL is widely used for the removal of traces of water as well as other impurities with polar characteristics from final as well as intermediate products in the chemical, pharmaceutical, food and beverage industries.

- Silica gel in granular form in packed beds is handled in a similar manner as described above for ACTIVATED CARBON.

For regeneration in this case hot gases are passed through the bed.

- BENTONITE has also found wide usage for a wide range of liquid purification applications in industries similar to 2) above.

Regeneration can be carried out in certain cases.

TYPICAL OPERATIONAL SEQUENCE:

EXAMPLE B

- Catalyst

- Ion-exchange material

BED MATERIAL

- Acids

- Alkalis

REGENERATION

Catalysis of liquids is widely practised in the production of organic chemicals and some food products.

Metals such as platinum, nickel, palladium, vanadium, etc. are often employed in the plated or sintered form, normally finely divided and mixed as a suspension in the liquid to be catalysed.

Raney nickel is an example of this procedure.

Packed beds of such material using for example kieselguhr as inert carrier would obviate the necessity of filtration with the state of the art methods.

A further advantage is the possibility of in-situ regeneration of the catalyst.

Ion-exchange processes abound.

Softening and deionisation of water are well known examples.

For batch-type operations and many continuous operations the employment of the packed bed system depicted above have decided advantages over state of the art static filled columns.

WATER APPLICATIONS - STATE-OF-THE-ART

Vs MILLER SYSTEM

Contents of this chapter:

First of all it is necessary to examine state-of-the-art apparatus and systems to pinpoint the reasons for the global failure to protect the environment. The collective will is not failing, rather it is the state-of-the-art apparatus that is failing to fit the purpose.

The reasons for this are highlighted by the CHART below.

In effect the compact FILTER PRESS was seen to be the model for all further design developments concerning LIQUID PURIFICATION. With little or no regard to the possible deleterious consequences to the environment, the exposed design of the filter press was solved by simply encasing the bundle of filter elements in sealed pressure vessels. This has remained the design basis of state-of-the-art liquid purifying apparatus for almost a century.

Nobody can expect the very filters making up the state-of-the-art that cause a large part of the environmental pollution are capable of solving the very problems they cause.

Summary

State of the art liquid purification apparatus fail to provide the means for economically viable media regeneration in the separation range 10-10 - 10-6 m.

MORE: “FAILURE STATE-OF-THE-ART - WHY?”

The MILLER residue plants operate with vacuum and provide THREE basic modes of operation:

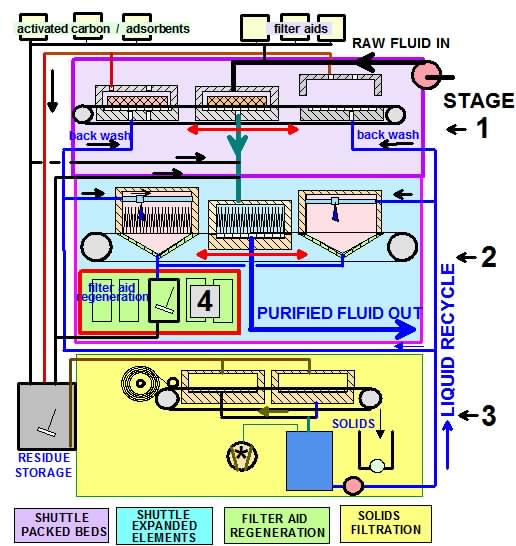

Comprised of four individual innovative liquid purification stages this system is designed to sequentially produce a wide variety of common consumer products.

The idea is to open up to the global market the possibility of installing a single plant for the local production of a whole gamut of consumer or industrial products conventionally requiring a large number (e.g. 5-10) of separate plants that often operate on a seasonal basis only and remain unused for long periods.

Examples are SUGAR REFINING, BEER BREWING, WINE MAKING, PHARMACEUTICALS, FRUIT JUICES, WATER, EDIBLE OILS, CHEMICALS.

|

Ref.: see previous Figure “MILLER UNIVERSAL SYSTEM” |

||

|

RESERVOIR & GROUND WATER |

||

|

STAGE 2 |

STAGE 4 |

WATER PURIFICATION |

|

STAGE 3 |

SOLIDS RESIDUE RECOVERY |

|

Reservoir and ground waters are becoming increasingly polluted from dumped industrial and domestic waste as well as agricultural chemicals.

Miller Systems can provide surety of supply of pristine potable water at all times and in times of emergency.

|

Ref.: see previous Figure “MILLER UNIVERSAL SYSTEM” |

||

|

SURFACE RUN-OFF WATER |

||

|

STAGE 1 |

CLARIFICATION |

|

|

STAGE 2 |

STAGE 4 |

PURIFICATION |

|

STAGE 3 |

RESIDUE RECOVERY |

|

State-of-the-art water purification technology often cannot handle the purification of surface run-off water such as rivers and streams to potable quality.

The MILLER STAGE GROUPING illustrated above can guarantee an economic solution over a wide range of RUN-OFF WATER QUALITIES.

|

Ref: see previous figure “MILLER UNIVERSAL SYSTEM” |

||

|

SUGAR, (stages 1, 2, 4) |

||

|

STAGE 1 |

RAW JUICE FILTRATION |

|

|

STAGE 2 |

STAGE 4 |

JUICE PURIFICATION |

|

STAGE 1 |

EFFLUENT RECYCLING |

|

State-of-the-art refining of both beet and cane sugar is based on technology developed almost 2 centuries ago.

The processes are outdated and inefficient.

Recent bio-fuel developments based on starch as well as sucrose have opened up this field to further development.

Sugar production would profit from improved heat energy conservation and improved juice purification resulting in a considerable reduction in carbon consumption and up to a 10% increase in sucrose yield.

Bio-fuels from both sucrose and starch can be produced efficiently with almost identical production technology.

These processes can be included in the PRODUCTION MENUS of future plants based on a single MILLER UNIVERSAL SYSTEM.

|

Ref: see previous figure “MILLER UNIVERSAL SYSTEM” |

||

|

VEGETABLE OIL |

||

|

STAGE 1a |

OIL EXTRACTION |

|

|

STAGE 2 |

STAGE 4 |

OIL PURIFICATION |

|

STAGE 1b |

EFFLUENT RECYCLING |

|

With MILLER UNIVERSAL SYSTEMS vegetable fats and bio-fuels can be produced in plants that are similar to those for the production of bio-fuels from sucrose and starch.

THE FUTURE OF ALL LIQUID PROCESSING LIES WITH FLEXIBLE PRODUCTION FACILITIES CAPABLE OF SWITCHING PRODUCTS AT SHORT NOTICE ACCORDING TO THE LOCAL AVAILABILITY OF RAW MATERIALS OR THE DEGREE OF LOCAL CONSUMER DEMAND.

|

Ref: see previous figure “MILLER UNIVERSAL SYSTEM” |

||

|

BEER (stages 1, 2, 3, 4) |

||

|

STAGE 3 |

MASH FILTRATION |

|

|

STAGE 2 |

STAGE 4 |

WORT PURIFICATION |

|

STAGE 2 |

STAGE 4 |

BEER PURIFICATION |

|

STAGE 3 |

YEAST RECOVERY |

|

|

STAGE 1 |

EFFLUENT RECYCLING |

|

State-of-the-art brewers are universally convinced that their technology after thousands of years of development has now reached a zenith of perfection and should not be tampered with by over-zealous innovators.

The reality is that the average brewery comprises a proliferation of a multitude of apparatus producing 5-10 litres of potent bio-effluent for each litre of beer produced.

For the MILLER UNIVERSAL SYSTEM beer is just another set of liquids for purification when barley or malt is available for meeting a demand and the aim is quality beer with zero effluent.

|

Ref: see previous figure “MILLER UNIVERSAL SYSTEM” |

||

|

WINE (stages 1, 2, 3, 4) |

||

|

STAGE 1 |

CRUSH JUICE FILTRATION |

|

|

STAGE 2 |

STAGE 4 |

JUICE PURIFICATION |

|

STAGE 2 |

STAGE 4 |

WINE PURIFICATION |

|

STAGE 3 |

YEAST RECOVERY |

|

|

STAGE 1 |

EFFLUENT RECYCLING |

|

It is common knowledge that an abundance of bad wine is being imposed on an undeserving public. This phenomenon has to be studied more closely and a solution sought within the framework of the Miller Universal System.

The goal is the availability of bulk wine with a consistently good quality with zero effluent.

|

Ref: see previous figure “MILLER UNIVERSAL SYSTEM” |

||

|

CHEMICALS / PHARMACEUTICALS |

||

|

STAGE 1a |

PRIMARY PURIFICATION |

|

|

STAGE 2 |

STAGE 4 |

STERILE PURIFICATION |

|

STAGE 3 |

EFFLUENT RECYCLING & SOLIDS RECOVERY |

|

|

STAGE 1B |

GAS PURIFICATION & RECYCLING |

|

|

ROBOT |

||

- ACTIVATED CARBON is perhaps the most widely used liquid purifying agent in the liquid processing industries.

It has universal application ranging from water purification to chemical purification in the chemical and pharmaceutical industries.

The centre Stage 1 of the SHUTTLE GROUP 1-3 is reserved for purification. After purification the contents are forced from the chamber and the PLEATED BUNDLE is transported to the waiting chamber 2 or 3 for media regeneration by

OPERATION

- high pressure jets of cleaning fluid,

- ultra-sonic generator

and - chemical cleaning.

Filter aid is regenerated separately (illustrated below the shuttle group) and recycled to Stage 1 at the start of the cycle.

STATE-OF-THE-ART LIQUID PURIFICATION

(the problems)

- Immediate reaction to changing demand

- Planned campaigns for seasonal products

- Quick amortisation of the capital investment

- Quick turn-around when changing product

- Elimination of effluent

- A production flexibility as yet unknown

The main advantages of such a system are

MILLER UNIVERSAL SYSTEM

THE MILLER SYSTEMS ENABLE THIS.

- ZERO EFFLUENT

- ONLY USABLE SOLID, LIQUID OR GASEOUS BYPRODUCTS ALLOWED TO LEAVE THE PLANT.

- ALL TOXIC RESIDUES TO BE DESTROYED/ DEGRADED AND MADE HARMLESS WITHIN THE PLANT.

- THE INTERNAL GASEOUS ENVIRONMENT OF THE PLANT TO BE MAINTAINED AT A HEALTH PROMOTING STANDARD.

Popular wisdom has it that good chemists also make good cooks.

Like top cooks they also tend to leave the mess they make for others to clean up.

Even today many chemical plants in the heat of production resemble kitchens in full swing.

There are the smells, the spills, the hectic and anything left over either goes down a drain or lands on a tip.

Out of sight out of mind!

Back to the test tubes!

Between the test tubes and the full-scale plant a universally applicable ROBOTIC PILOT PLANT should be available to ensure that the following criteria are met in the FULL SCALE PLANT:

In the following cycle the bed in Units 21 or 3 is returned to Unit 1 to continue the operation.

Purification:

- Liquids for purification are pumped through beds in UNIT 1 containing powdered and/or granular activated carbon.

- On reaching an upper limit of concentration of impurity in the filtrate the bed is washed through with an appropriate liquid to recover the product contained in the bed.

- The bed in Unit 1 is then transported to the available Unit 2 or 3 for regeneration.

Bed regeneration:

- Heated gases or solvents with appropriate temperature or polarity are passed through the bed now in Unit 2 or 3 to dislodge and replace the molecules adsorbed on the surfaces of the carbon.

- Hot inert gas or steam is passed through beds to remove solvents.

MORE: “SOLIDS RECOVERY”