|

|

|||||||||||||

|

|||||||||||||

|

WHY HAS STATE-OF-THE-ART- |

|

Contents of this chapter: |

|

|

The reason is depicted on the chart below. |

|

|

|

||||||||

|

Filters for solids |

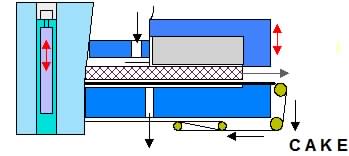

This led to the proliferation of a large number of specialized filter designs depicted on the left and right hand side The prime object of the |

Filters for liquid |

|||||||||

|

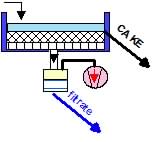

ROTARY VACUUM FILTER |

|||||||||||

|

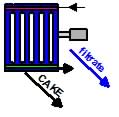

VERTICAL LEAF |

|||||||||||

|

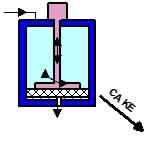

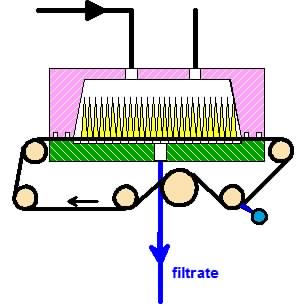

PRESSURE BELT FILTER |

EXPANDED SURFACE |

||||||||||

|

In effect the compact progenitor FILTER PRESS was taken as the model for all further design developments concerning FLUID PURIFICATION. |

|

|

|

|||||||||