|

|

|||||||||||||

|

|||||||||||||

|

MILLER UNIVERSAL MULTI-PRODUCT |

|

Contents of this chapter: |

|

|

|

|||

|

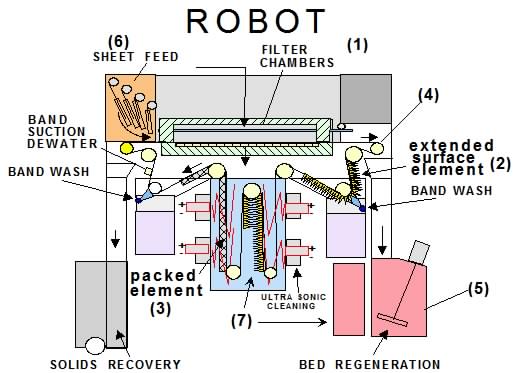

The robotic system depicted below eliminates manual intervention in the production process as well as solving the problem of contaminated effluent of both liquid and gaseous origin. |

|||

|

|||

|

The above depicted liquid processing plant illustrates the essential features of a plant capable of functioning in a ROBOTIC manner: |

|||

|

|||

|

Application areas of a liquid purification robot: |

|||

|

|||

|

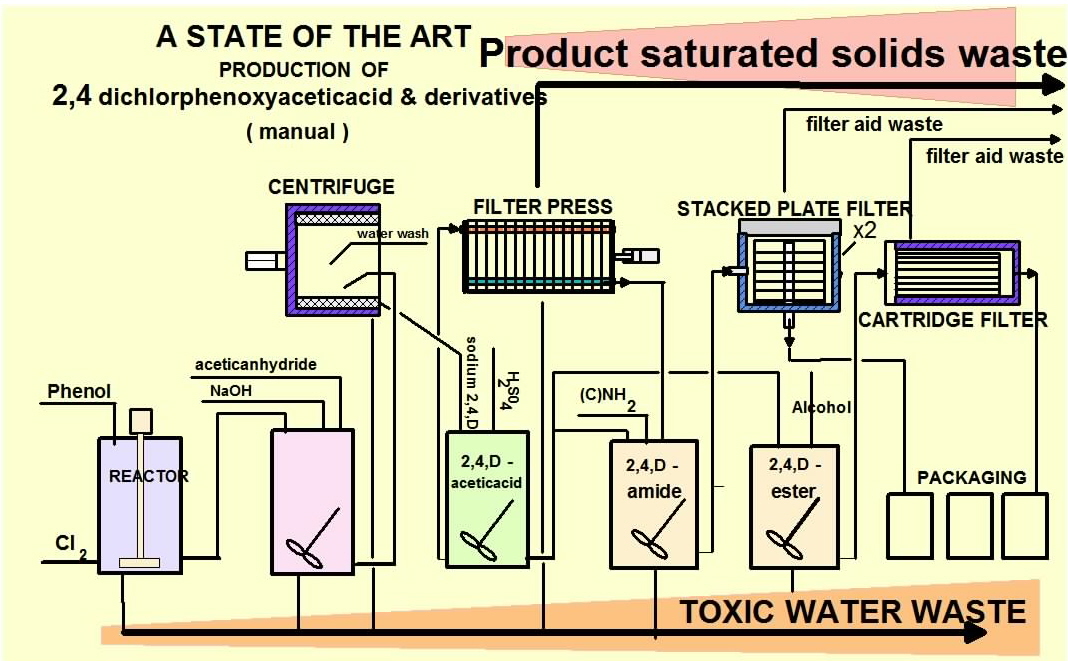

Below is the schema of a typical multi-product chemical plant. Based on the raw materials phenol and chlorine a group of chlorinated organic herbicides are produced in manual operation. |

|||||

|

|||||

|

It is imperative that technology is devised to |

|||||

|

|||||

|

Improved apparatus and systems must be devised to comply with more stringent environmental regulations if global fresh water resources are to be saved. |

|||||

|

|||||

|

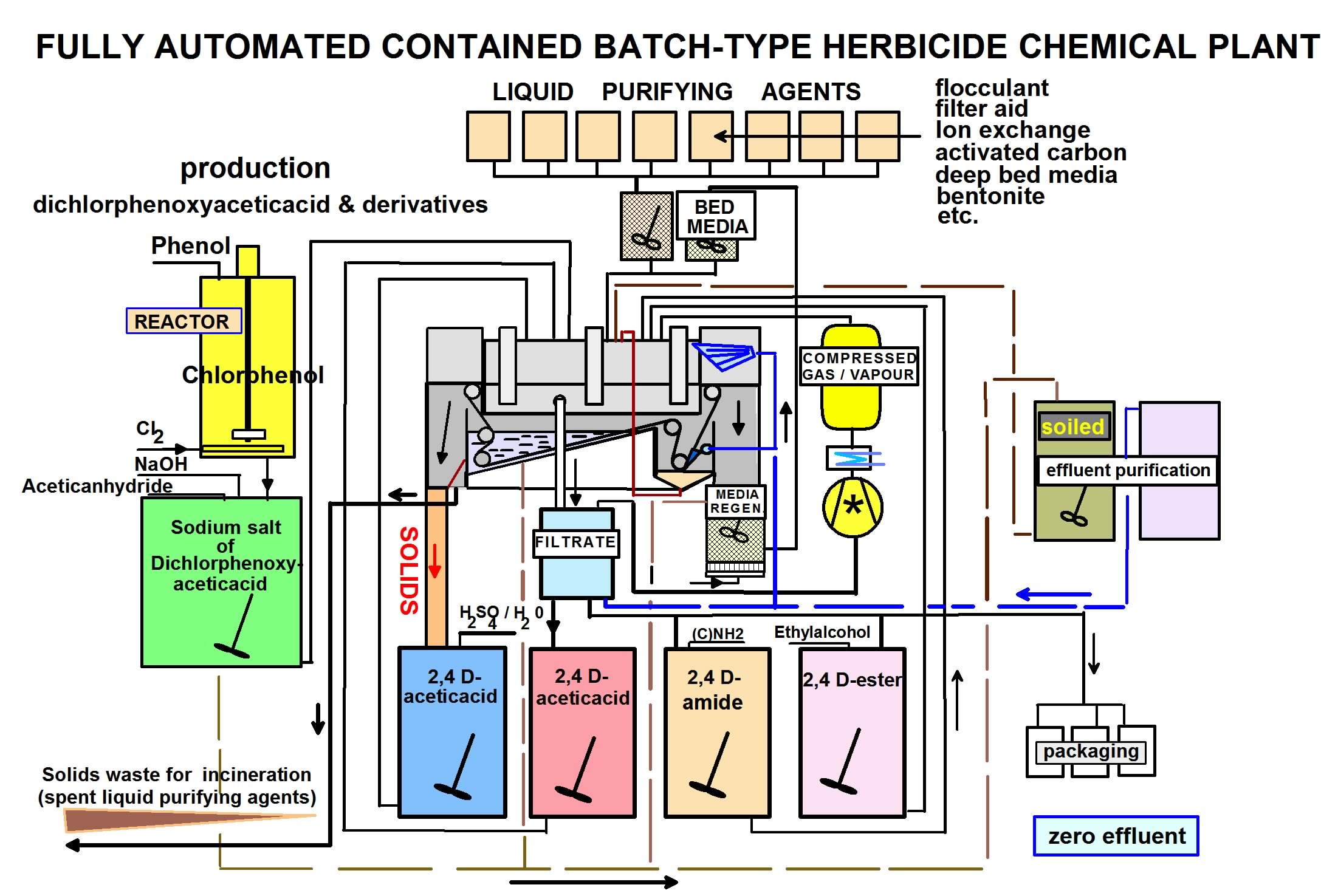

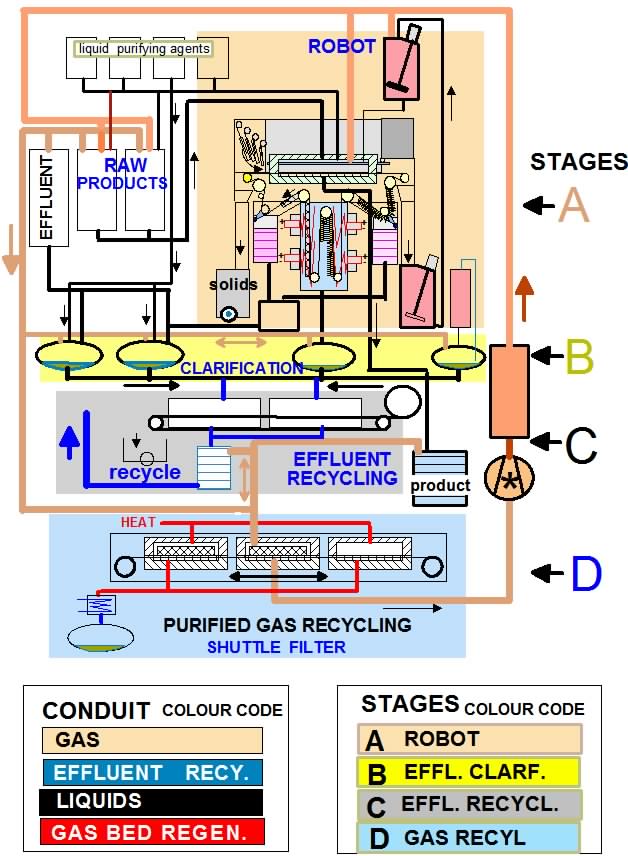

The above schema illustrates how a single sealed MILLER ROBOT-LIKE FILTER carries out ALL the solids recovery and liquid purification operations. All effluent is purified and recycled. |

|||||

|

In the above depicted small scale robot-like MILLER PLANT the process filter itself cleans and recycles the effluent produced. |

|||

|

|||

|

|||

|

GAS RECYCLING |

|

In state-of-the-art liquid processing plants little if any provision is made for protection of the internal and external environment concerning the escape of vapours, odours, volatiles, etc. from the processing equipment. In fact, it is well known that many such escapes occur under the cover of darkness or the plants are located on or near the sea with the prevailing wind heading out to sea. |

|

|

|

|||||||||

This innovative robotic system opens up new opportunities for the production of a large number of entirely disparate products with a single plant especially suited for supplying clusters of small communities with the whole gamut of their special local liquid processing requirements.

This innovative robotic system opens up new opportunities for the production of a large number of entirely disparate products with a single plant especially suited for supplying clusters of small communities with the whole gamut of their special local liquid processing requirements.